PVC Placemat Manufacturing: Essential Raw Material Testing for Quality Assurance

Raw material testing is a critical checkpoint in PVC placemat manufacturing, ensuring that incoming materials meet stringent quality and safety standards. For importers, wholesalers, and distributors, this step guarantees that high-quality PVC placemats are consistent, compliant, and ready for global markets. This article outlines the detailed process, standards, and equipment used in raw material testing, providing insight into how we ensure product reliability in PVC table mat production.

Key Parameters for Raw Material Testing

To produce high-quality PVC placemats, the following raw material properties are rigorously tested:

- Purity of PVC Resin: Ensures minimal impurities to prevent defects during extrusion.

- Particle Size Distribution: Uniform particle size is critical for consistent mixing and processing in PVC place mat manufacturing.

- Moisture Content: Excess moisture can cause processing issues, such as bubbling or uneven extrusion.

- Chemical Composition: Verifies that plasticizers (e.g., DINP, DOTP), stabilizers (e.g., calcium-zinc), and additives comply with environmental standards like REACH and RoHS.

- Physical Properties: Tests include plasticizer volatility, stabilizer heat resistance, and filler compatibility to ensure eco-friendly PVC materials.

Standardized Testing Process

Sample Collection

- Random samples are drawn from each batch of raw materials (PVC resin, plasticizers, stabilizers, fillers) to ensure representativeness.

- Sampling follows ISO 2859-1 standards for statistical reliability.

Laboratory Analysis

- Spectroscopy: Fourier Transform Infrared (FTIR) spectroscopy verifies chemical composition and detects contaminants.

- Particle Size Analysis: Laser diffraction analyzers measure PVC resin particle size distribution for uniformity.

- Moisture Testing: Gravimetric moisture analyzers confirm low moisture content (<0.5%) to prevent processing defects.

- Environmental Compliance Testing: Gas chromatography-mass spectrometry (GC-MS) checks for restricted substances, ensuring eco-friendly PVC materials.

Data Documentation

- Test results are recorded in a batch-specific database, linked to unique batch numbers for full traceability.

- Certificates of Analysis (COA) are generated for each batch, available for distributor verification.

Handling Non-Conforming Materials:

- Materials failing to meet standards are rejected or downgraded for non-critical applications.

- Suppliers are notified immediately to resolve quality issues and maintain supply chain integrity.

Advanced Testing Equipment

To ensure precision in raw material testing, we utilize state-of-the-art equipment:

- FTIR Spectrometer: Identifies chemical composition with high accuracy.

- Laser Particle Size Analyzer: Ensures uniform particle distribution for optimal PVC placemat manufacturing.

- Moisture Analyzer: Detects trace moisture to prevent processing issues.

- GC-MS System: Confirms compliance with environmental regulations like REACH and FDA.

Advanced Testing Equipment

Raw material testing is a key link in the quality control of PVC placemats, ensuring that the raw materials meet production standards through strict purity, particle size, moisture content, chemical composition, and physical property testing. The standardized testing process (sampling, laboratory analysis, data recording, and non-conforming handling) combined with equipment calibration, batch traceability, and rapid feedback mechanism lays the foundation for subsequent formula design and stable production.

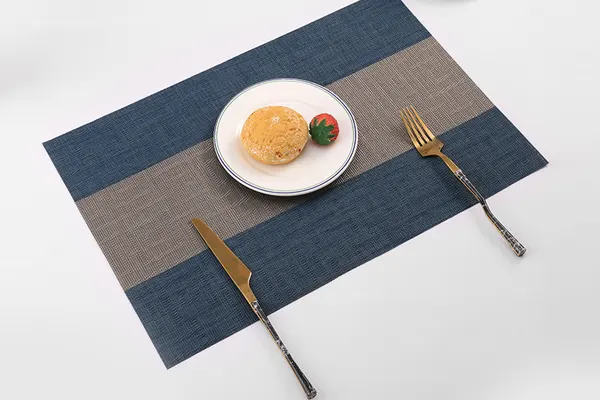

Latest placemats

Cooperation Cases

Explore more meal mat solutions

Are you ready to start your meal mat procurement journey?

Are you ready to start your meal mat procurement journey?

We will provide perfect solutions and competitive quotations based on your procurement needs, including material, quantity, logo customization, and other factors