Can PVC placemats be customized with logos or specific patterns for branding?

Introduction

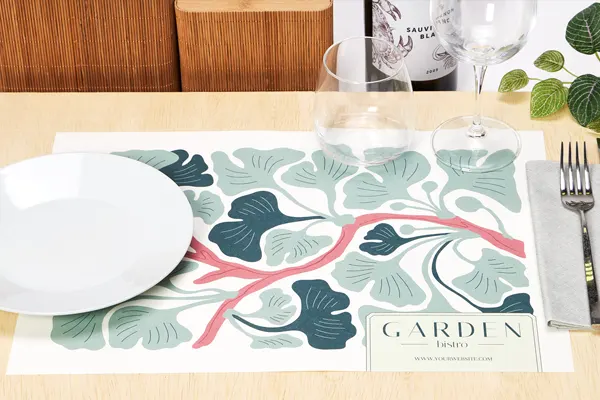

1、 Why customize PVC placemats for brands?

PVC placemats have become a popular choice in the hotel and home decor industry due to their waterproofing, ease of maintenance, and cost-effectiveness. Here are several reasons to choose PVC placemats for brand customization and promotion:

1. Brand recognition

The logo or unique pattern on the placemat can enhance the brand identity, making it immediately recognizable by customers (imagine what it feels like to see the Hermes logo printed on a PVC placemat).

2. Market differentiation

Customized design helps meal mat wholesalers stand out in a fiercely competitive market, attracting customers seeking meal mat customization and brand promotion.

3. Enhance aesthetic appeal

Customized patterns can be consistent with specific themes or interior decorations, enhancing the product’s market competitiveness, such as using Christmas patterned placemats during Christmas.

4. Promotion opportunities

Brand placemats can serve as subtle marketing tools for restaurants, hotels, or retail venues, invisibly increasing the profit margin of catering enterprises.

2. What are the customization techniques for PVC placemats?

1. Screen printing

Screen printing is a widely used technique for adding logos and patterns to PVC placemats. It uses ink to print specific brand patterns onto the surface of the placemat. This printing method is very suitable for monochrome promotional patterns or brand logos.

Advantages: Large scale batch printing has lower costs, durable printing, and bright colors.

Disadvantages: Limited to simpler designs; Multi color printing may increase costs.

2. Digital printing

Advantages: High precision, support for complex designs, very suitable for small batch production.

Disadvantages: The unit cost of small orders is relatively high; Quality control is required to ensure printing durability.

3. Embossing and indentation

Advantages: Elegant and exquisite appearance, durable design, and no fading.

Disadvantages: Mold setup costs are relatively high; Limited to simpler designs.

4. Heat transfer printing

Advantages: Bright colors, support for multi-color design, relatively fast processing speed.

Disadvantages: Durability may vary depending on the quality of the transfer film.

5. Interior Decoration (IMD)

Advantages: Excellent durability, seamless integration, high-quality finish.

Considerations: High initial cost; Most suitable for large-scale production.

3、 Key considerations for importers and wholesalers

Although customized PVC placemats provide great opportunities for logo customization and brand promotion, importers and wholesalers must consider several factors to ensure success:

1. Target market preference

Understand the preferences of the target market. For example, minimalist logos may attract modern hotel customers, while complex patterns may be suitable for home decor wholesalers. We suggest that you communicate with the manufacturer to understand customized solutions from other customers in various markets and create designs that resonate with the audience.

2. Minimum Order Quantity (MOQ)

Customization usually involves setting costs, such as mold design and manufacturing, as well as basic procurement of raw materials. Manufacturers may require a minimum order quantity to offset these costs. Minimum order quantity with placemat manufacturers to meet your inventory needs.

3. Durability and Quality

Ensure that the selected customization method maintains the functionality of the placemat. For example, printing design should be able to withstand regular cleaning, high temperatures, and wear, and some PVC placemats even have the ability to withstand dishwasher cleaning. Before placing a bulk order, please contact the placemat manufacturer to request a sample test report.

4. Regulatory compliance

PVC placemats must comply with safety and environmental regulations of the target market, such as FDA standards in the United States or REACH regulations in the European Union. Verify whether the materials and printing process meet these requirements. Otherwise, your PVC placemat is likely to encounter obstacles during customs clearance.

5. Cost and Value

Balancing the cost of customization and the perceived value of the final product is crucial. Although advanced technologies such as IMD and heat transfer printing provide high-quality results, simpler methods such as screen printing may be more cost-effective for budget conscious customers.

4、 How to start using customized PVC placemats

Are you ready to enhance your brand with customized PVC placemats? Please follow the steps below:

- Define your design: Create a logo or pattern that is consistent with your brand identity.

- Choose customization method: Consult your placemat manufacturer to select the best technology based on design complexity, budget, and order size.

- Request samples: Test customized sample prototypes of PVC placemats to ensure that the design meets your quality and durability standards.

- Place an order: Confirm the minimum order quantity, production schedule, and shipping details with the supplier.

Conclusion

Customizing PVC placemats with logos or specific patterns is not only possible, but also a strategic measure to increase brand awareness and enhance catering profit margins. Through a series of customization techniques such as screen printing, digital printing, embossing, heat transfer printing, and in mold decoration, each different placemat procurement manager can obtain satisfactory customization solutions. By collaborating with reputable manufacturers, you can produce high-quality branded placemats that meet market demand and regulatory standards. Please start exploring PVC placemat customization business immediately to make your product stand out in the fiercely competitive tableware industry.

Latest placemats

Cooperation Cases

Explore more meal mat solutions

Are you ready to start your meal mat procurement journey?

Are you ready to start your meal mat procurement journey?

We will provide perfect solutions and competitive quotations based on your procurement needs, including material, quantity, logo customization, and other factors