PVC Placemat Manufacturing: Expert Formulation Design for High-Performance Mats

Formulation design is a pivotal stage in PVC placemat manufacturing, determining the balance of durability, flexibility, and environmental compliance in the final product. A well-crafted formulation ensures high-quality PVC place mats meet specific performance requirements, such as heat resistance, flexibility, and aesthetic appeal, while maintaining cost-effectiveness. This article details the formulation design process, key considerations, and how it contributes to producing reliable PVC place mats for global markets.

Components of a PVC Placemat Formulation

A robust formulation for high-quality PVC placemats includes the following components, carefully balanced to meet market demands:

- PVC Resin (50-70%): The backbone of the table mat, providing structural integrity. High-molecular-weight PVC resin is selected for superior strength and extrusion compatibility.

- Plasticizers (20-40%): Materials like DINP or DOTP enhance flexibility and processability, ensuring compliance with food safety standards (e.g., FDA, EU 10/2011).

- Heat Stabilizers (1-3%): Calcium-zinc stabilizers prevent thermal degradation during processing, ensuring long-term durability.

- Fillers (5-20%): Heavy calcium carbonate optimizes cost while maintaining hardness and surface smoothness.

- Functional Additives: Antibacterial agents, UV stabilizers, or food-grade pigments are incorporated to meet specific requirements, such as antimicrobial properties or color vibrancy.

Formulation Design Process

Requirement Analysis

- Specifications are defined based on end-use applications, such as commercial dining, hospitality, or residential settings.

- Key performance criteria include heat resistance (up to 80°C), flexibility, and compliance with environmental standards like REACH and RoHS.

Laboratory Testing

- Small-scale trials are conducted to test various raw material ratios, adjusting plasticizer and filler levels to achieve desired properties.

- Tests evaluate tensile strength, elongation, and thermal stability using standards like ASTM D638 for tensile properties.

Performance Validation

- Formulations undergo rigorous testing for durability, flexibility, and environmental safety.

- For example, plasticizer migration tests ensure compliance with EU 10/2011 for food-contact applications.

Optimization and Finalization

- Based on test results, formulations are fine-tuned to balance performance and cost.

- Final formulations are documented with precise ratios and stored in a batch-specific database for consistency.

Key Considerations in Formulation Design

To deliver high-quality PVC table mats, the following factors are prioritized:

- Environmental Compliance: All components meet REACH, RoHS, and FDA standards, ensuring eco-friendly PVC materials suitable for global distribution.

- Cost Efficiency: By optimizing filler and plasticizer ratios, we maintain competitive pricing without compromising quality.

- Material Compatibility: Additives are selected to avoid chemical interactions, ensuring stability during processing and in the final product.

- Customizability: Formulations can be tailored for specific needs, such as enhanced antibacterial properties or UV resistance for outdoor use.

Advanced Tools and Expertise

Our formulation design process leverages cutting-edge technology and expertise:

- Formulation Software: Tools like SAP or custom ERP systems calculate optimal material ratios based on performance and cost parameters.

- Testing Equipment: Universal testing machines and thermal analyzers ensure formulations meet industry standards.

- Experienced Chemists: Our team of material scientists ensures formulations are optimized for both performance and scalability.

Why Our Formulations Stand Out

As a leading PVC table mat manufacturer, we prioritize formulation design to deliver products that meet the highest industry standards. Our formulations ensure consistent quality, compliance, and performance, making our PVC table mats a preferred choice for global markets. Whether you need standard or customized solutions, our expertise guarantees products that enhance your supply chain reliability.

Formulation design lays the groundwork for the next stage: mixing, where raw materials are blended into a uniform compound. Interested in learning more about our PVC table mat manufacturing process or exploring tailored formulation options? Contact us to discuss your requirements or request samples.

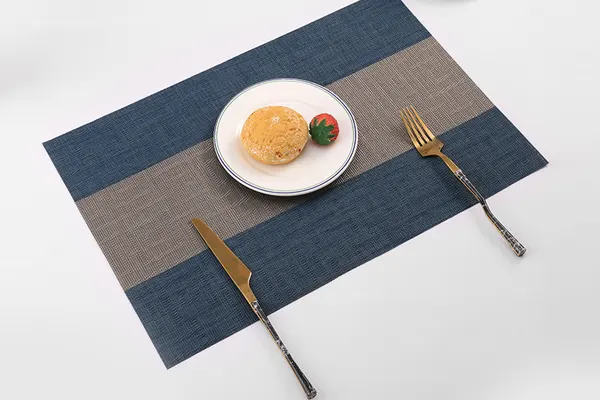

Latest placemats

Cooperation Cases

Explore more meal mat solutions

Are you ready to start your meal mat procurement journey?

Are you ready to start your meal mat procurement journey?

We will provide perfect solutions and competitive quotations based on your procurement needs, including material, quantity, logo customization, and other factors