PVC Mat Manufacturing: Raw Material & Quality Assurance Guide

Raw material procurement is the cornerstone of PVC placemat manufacturing, directly impacting product quality, performance, and market competitiveness. High-quality raw materials ensure that PVC table mats meet durability, eco-friendliness, and functionality standards, making them ideal for wholesale and distribution markets. This article explores the critical steps, standards, and considerations in procuring raw materials for PVC placemat production, offering insights into selecting a reliable supplier for high-quality PVC table mats.

Core Raw Materials for PVC Table Mats

Producing high-quality PVC table mats requires carefully selected raw materials:

Polyvinyl Chloride (PVC) Resin: The primary base material, providing structural strength and flexibility. High-molecular-weight, uniform-particle-size PVC resin is preferred for stable extrusion processes.

- Plasticizers: Such as DINP (Diisononyl Phthalate) or DOTP (Dioctyl Terephthalate), enhancing flexibility and processability while meeting food safety standards like FDA or EU 10/2011.

- Heat Stabilizers: Calcium-zinc stabilizers prevent degradation during high-temperature processing, ensuring long-term product stability.

- Fillers: Heavy calcium carbonate optimizes cost and enhances hardness without compromising surface smoothness.

- Functional Additives: Food-grade pigments, antibacterial agents, or UV stabilizers are added to meet specific market demands for eco-friendly PVC table mats.

Standardized Procurement Process

Supplier Evaluation and Certification

- Select suppliers certified under ISO 9001 for quality management, ensuring reliable supply chains and consistent raw material quality.

- Prioritize partners compliant with environmental standards like REACH and RoHS, meeting stringent requirements for global markets.

- Conduct regular audits of suppliers’ production capabilities and quality control systems to guarantee long-term reliability.

Sample Testing and Validation

- Before procurement, samples are tested in laboratories to verify purity, particle size distribution, and chemical stability.

- Tests include volatile organic compound (VOC) levels, heat stability, and plasticizer migration rates to ensure compliance with international standards.

Contract and Specification Clarity

- Detailed contracts specify raw material requirements (e.g., PVC resin K-value, plasticizer environmental grade), delivery schedules, and batch traceability.

- Each batch is accompanied by a Certificate of Analysis (COA) for quality verification.

Logistics and Storage Management

- Raw materials are transported in moisture-proof, contamination-free packaging (e.g., sealed plastic bags or bulk bags) to preserve quality.

- Materials are stored in temperature- and humidity-controlled warehouses (20-25°C, <60% humidity) to prevent moisture or impurity issues.

Commitment to Quality and Sustainability

Understanding the priorities of importers and wholesalers, our raw material procurement emphasizes:

- Environmental Compliance: All materials meet REACH, RoHS, and FDA standards, ensuring seamless market access for eco-friendly PVC table mats

- Batch Traceability: Unique batch numbers enable full traceability from procurement to production, facilitating quality management and issue resolution.

- Sustainability: We prioritize recyclable or low-VOC plasticizers and stabilizers, aligning with global trends in sustainable PVC table mat manufacturing.

Why Partner with Us

As a dedicated PVC placemat manufacturer, we invest heavily in raw material procurement to deliver high-quality, cost-effective products that enhance your market edge. Our optimized procurement process ensures consistent quality and compliance, making our PVC table mats a trusted choice for distributors worldwide.

Next Steps: Explore Our Manufacturing Process

Raw material procurement is just the first step in PVC table mat manufacturing. Subsequent stages, such as raw material testing, formulation, and extrusion, are equally critical to product performance. Interested in learning more about our end-to-end production capabilities or requesting customized PVC table mat solutions? Contact us for detailed insights or to request samples.

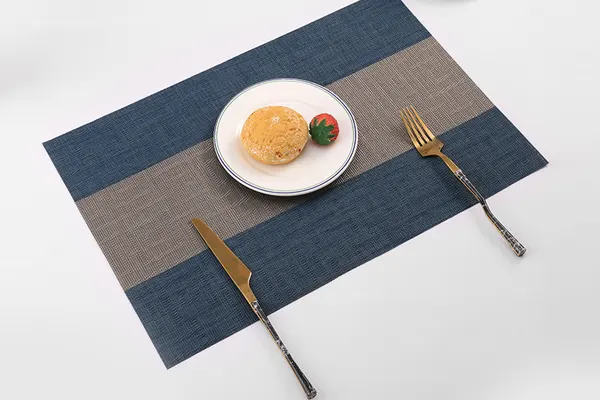

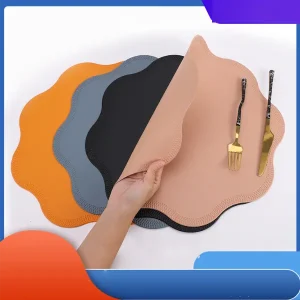

Latest placemats

Cooperation Cases

Explore more meal mat solutions

Are you ready to start your meal mat procurement journey?

Are you ready to start your meal mat procurement journey?

We will provide perfect solutions and competitive quotations based on your procurement needs, including material, quantity, logo customization, and other factors